DATA-RICH HIGH FIDELITY STRUCTURAL CHARACTERISATION

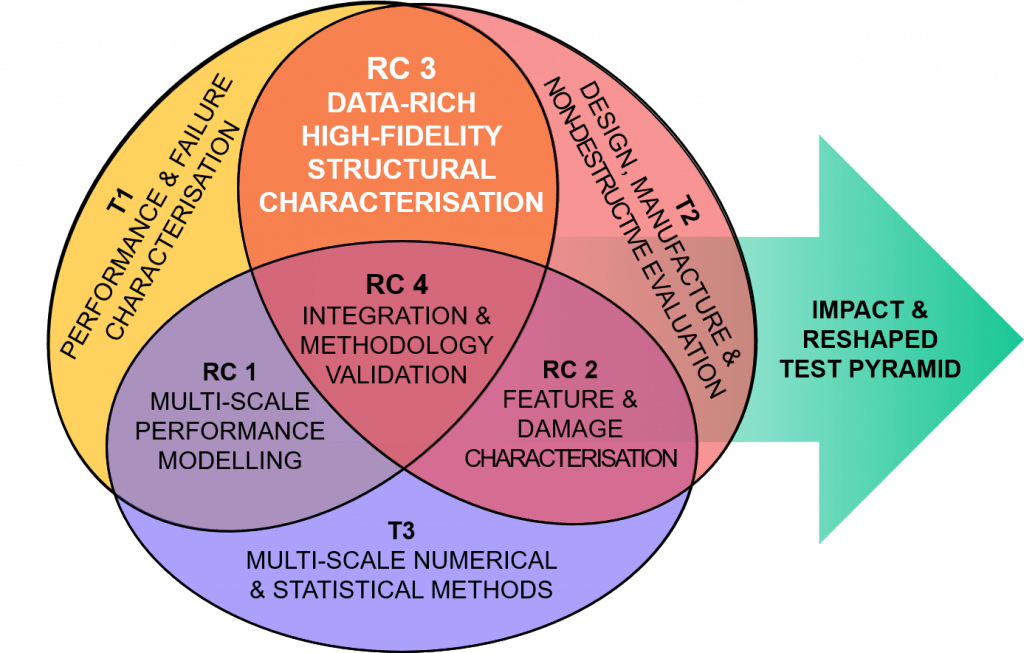

The vision of CerTest is realised through four flexible and highly interlinked and interdependent Research Challenges (RC1‐RC4), utilising a multiscale approach drawing on the expertise highlighted by the Themes (T1‐T3).

Fig. 1 Interconnection of Research Challenges (RCs) and Themes (Ts) leading to impact.

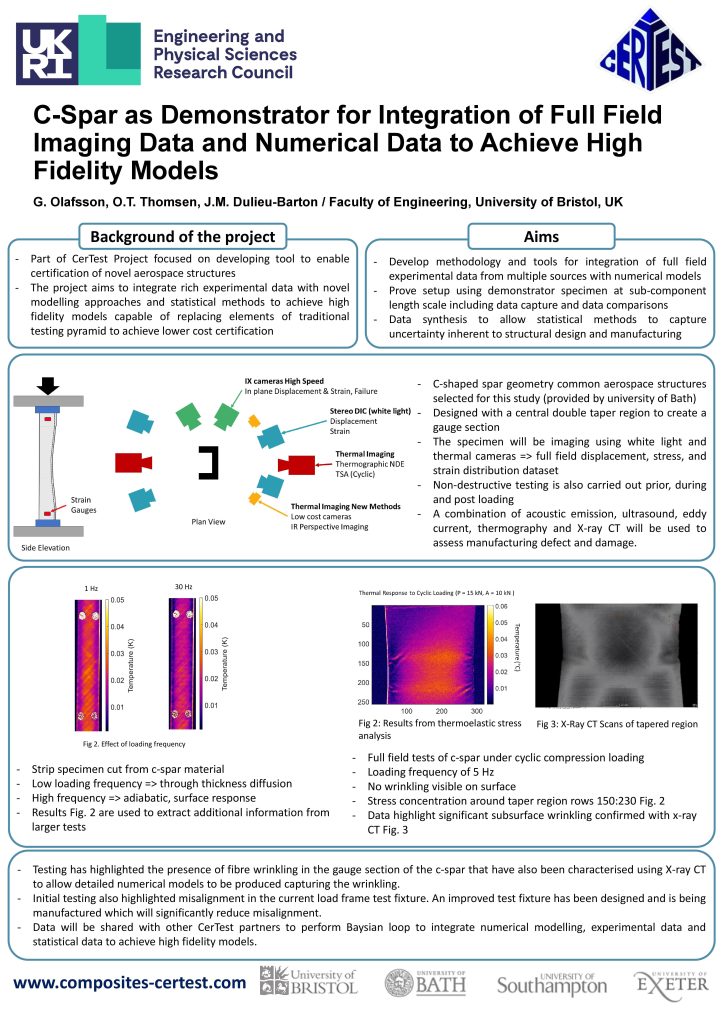

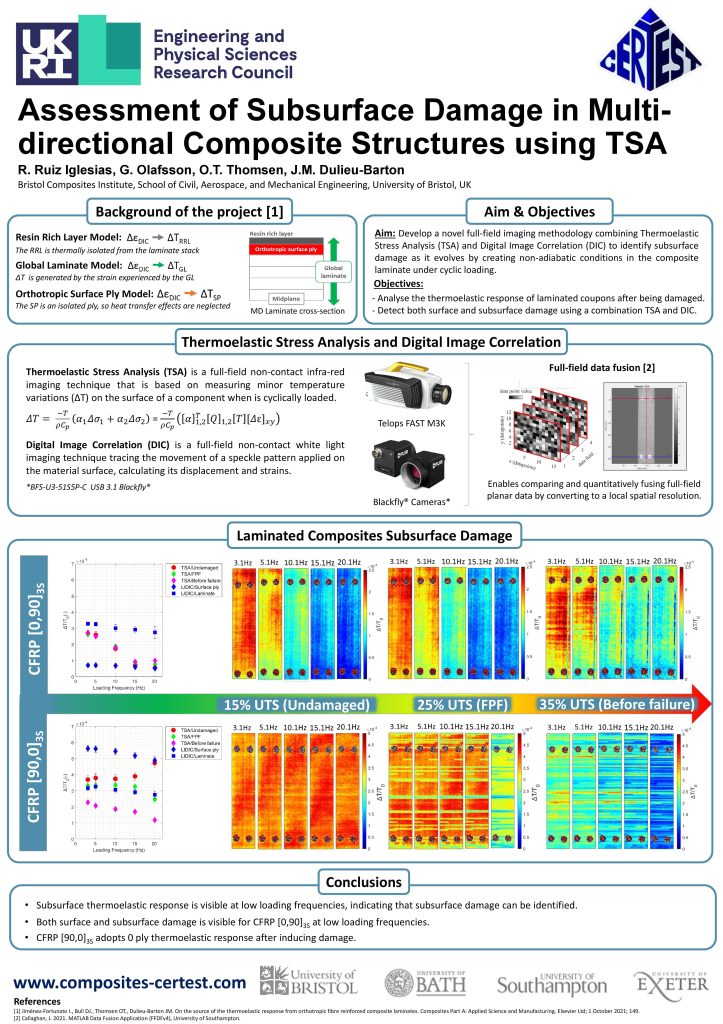

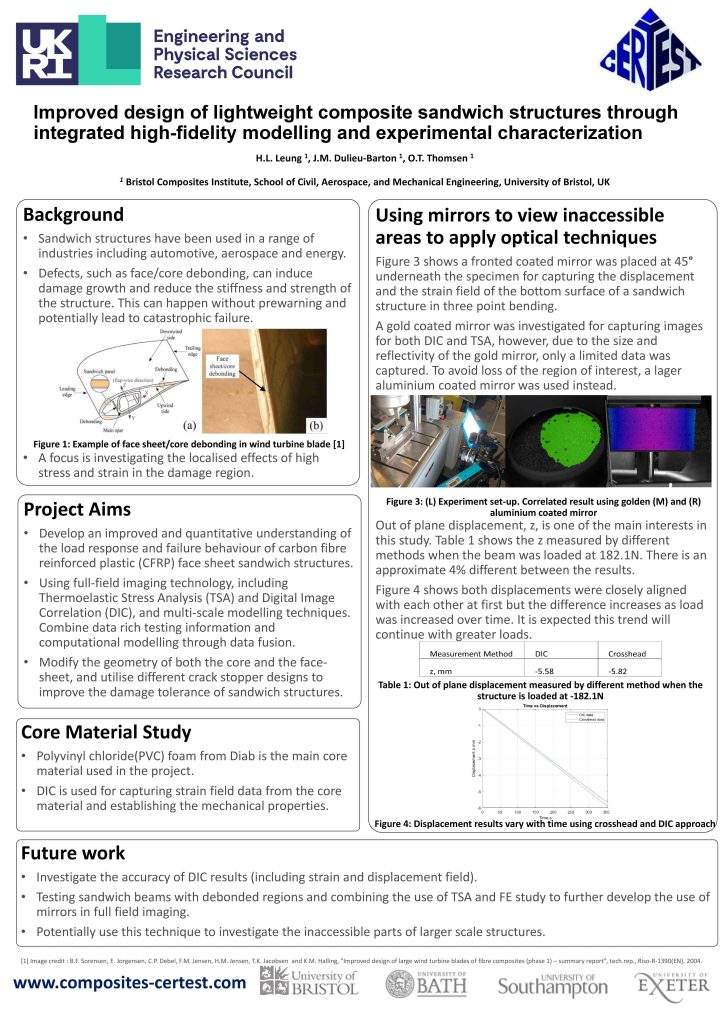

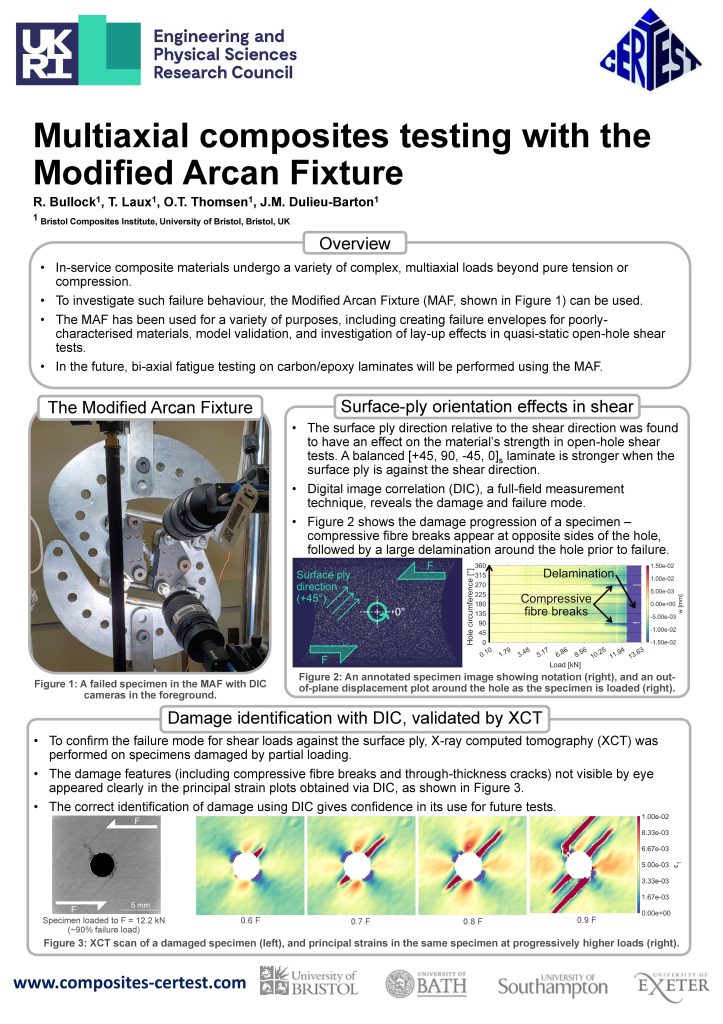

The overall aim of RC3 is to provide the scientific foundation for a novel high‐fidelity paradigm for data‐rich testing of structures subjected to complex and realistic multi‐axial loading. This is underpinned by establishing a means of obtaining the stress, strain and deformation developed in a complex structure subjected to realistic loading using non‐contact full‐field imaging, across multiple scales, i.e. near internal meso/micro features (identified in RC2) and globally across the structure.

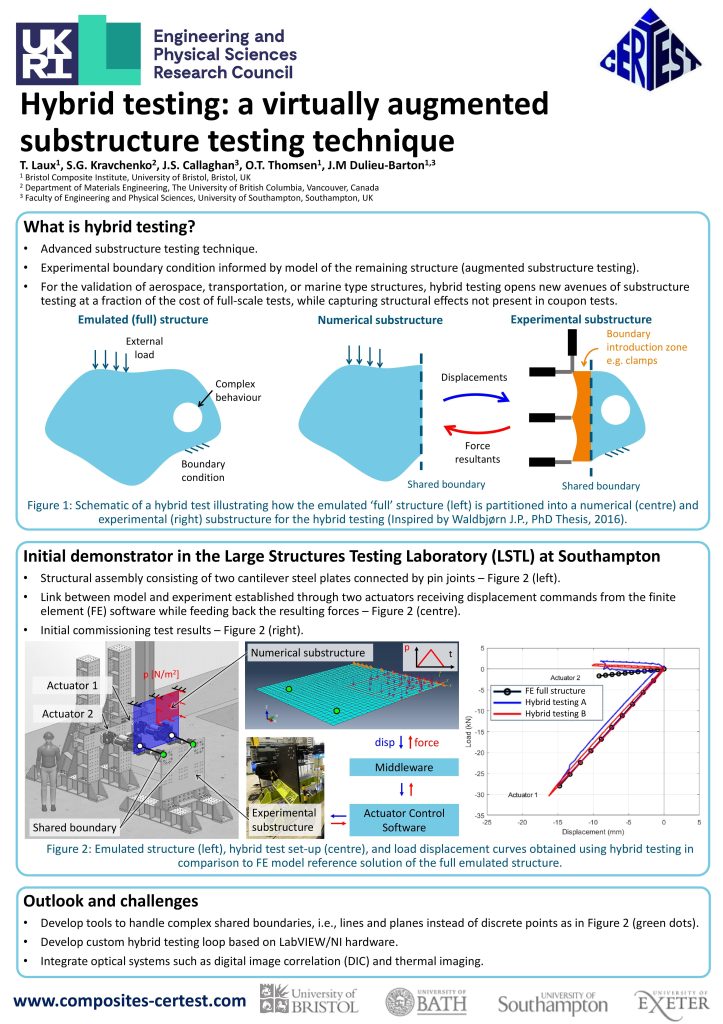

RC3 provides the ability to quantitatively identify the mechanisms that initiate damage experimentally, and cause it to propagate and lead to failure. The statistical Design of Experiments (DoE) approach developed in RC4 enables the definition of loads and boundary conditions for high‐fidelity experiments based on multi‐scale modelling outputs delivered in RC1. This, together with the development of an advanced ‘hybrid testing’ platform, allows the test configuration to emulate complex (multi‐axial) load states experienced in‐service. Hybrid testing will be enabled by actuation systems controlled by integrating algorithms from real‐time simulations (reduced order/low fidelity models RC1). Results from RC3 iteratively feedback into the models developed in RC1 to provide validation. RC4 integrates and synthesises statistical multi‐scale model results (RC1) with data‐rich experimental outputs obtained in RC3 to provide the overarching PG delivery from RC4.

There are several motivations for synchronous application of DIC and TSA relevant to the analysis of composite structures. TSA has the advantage that data can be obtained at a much greater spatial resolution than DIC as each sensor point in the IR detector is a measuring point.

Background and Motivation

A key part of the novelty in RC3 is devising methodologies to apply data‐rich full‐field imaging approaches to large components in a large structural testing facility. To the knowledge ofthe applicants, application of full‐field techniques on a structural scale has been limited, with few examples described in the open literature42. Underpinning RC3 is a recent Strategic Equipment Grant (‘Structures 2025 (S2025)’ EP/ EP/R008787/1) awarded to UoS in 2017, which provides the necessary full‐field imaging equipment to enable application at multiple scales across large structures. Recent reductions in cost of digital cameras and the availability of computing power to handle the large data sets from images have provided the opportunity to ‘up‐scale’.

RC3 Posters

Research Associates

Geir Olafsson

University of Bristol

Tobias Laux

University of Bristol

PhD Students

Rafael Ruiz-Iglesias

University of Bristol

Emily Leung

University of Bristol

University of Bristol